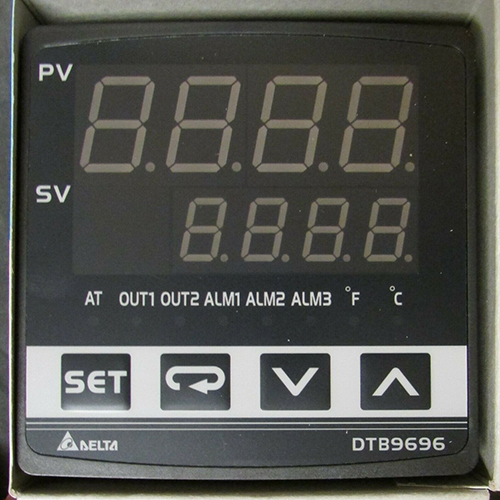

Delta Temperature Controller 4 Digit

Product Details:

- Surface Finish Smooth

- Features Good Quality

- Material MS

- Shape Rectangualr

- Warranty 1 year

- Feature Good Quality

- Click to View more

Delta Temperature Controller 4 Digit Price And Quantity

- 2000.0 INR

- 1 Number

Delta Temperature Controller 4 Digit Product Specifications

- Good Quality

- MS

- Good Quality

- Smooth

- 1 year

- Rectangualr

Delta Temperature Controller 4 Digit Trade Information

- 1

- Paypal, Cash in Advance (CID), Cheque

- 1 Number Per Day

- 2 Days

- No

- Within a certain price range free samples are available

- Asia

- All India

Product Description

A temperature controller is a device that regulates temperature by comparing a measured temperature to a desired setpoint and then producing an output to control a heating or cooling element.

How It Works

-

Sensor Input: A temperature sensor (e.g., thermocouple or RTD) measures the current temperature of the process.

-

Comparison: The controller compares this measured value to the desired setpoint.

-

Control Action: If there's a difference (error), the controller sends an output signal to a control element (heater, cooler, valve).

-

Feedback Loop: This continues as a loop to maintain the desired temperature.

Types of Temperature Controllers

| Type | Description |

|---|---|

| ON/OFF | Simplest form. Output is either fully ON or OFF. Best for less sensitive systems. |

| Proportional (P) | Reduces output as temperature nears setpoint. Prevents overshoot. |

| PID | Combines Proportional, Integral, and Derivative actions for precise control. |

| Fuzzy Logic / Adaptive | Uses logic-based decision-making for complex or variable processes. |

Main Components

| Component | Function |

|---|---|

| Sensor | Detects process temperature (e.g., thermocouple, RTD) |

| Controller Unit | Processes input, compares with setpoint, generates control output |

| Output Element | Controls heating/cooling (e.g., relay, SSR, analog signal) |

| User Interface | Allows configuration of setpoint, parameters, and displays temperature info |

Key Features

-

Setpoint Programming: Manual or automated setting of target temperature.

-

Auto/Manual Tuning: PID tuning for optimized response.

-

Alarms: High/low limit alerts.

-

Output Options: Relay, SSR, analog (420 mA, 010 V).

-

Communication: RS-485, Modbus, Ethernet for integration with SCADA or PLC systems.

-

Ramp/Soak Profiles: For applications like furnaces and ovens needing time-based temperature changes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free